MECHANICAL PROCESSING INDUSTRY

The I.L.M. Company Srl was founded by Luciano Flamini in 1981, in Aprilia, in the province of Latina, based on his entrepreneurial and technical skills, with the help of qualified men who contributed with their personal knowledge and experience in the precision mechanics sector.

Today I.L.M. Srl employs over 40 people, offering services suitable for the transformation of materials.

Since its creation, the scope of his Company was the custom processing of high precision mechanical products in the turning and milling fields; during the first years the company operated exclusively in army and civilian fields, then later it extended its production range to mechanical parts produced for the aerospace field.

The important partnership between I.L.M. Srl and AVIO Spa also makes it possible for the Company to participate constantly and actively to the production of important parts for programs such as:

• ASTER • ARIANE 6 • VEGA C • VEGA E

The I.L.M. Srl company increased its production field and obtained the UNI EN ISO 9001 certification in 1991,thanks to its highly specialized staff, and to the purchase of new generation machinery. The I.L.M.Srl Company now presents itself as a company capable of satisfying multiple requests from its customers. The company is flexible, even in its production planning, due to the need to answer short-term delivery orders.

The company now offers a wide range of services, such as:

• material supply (raw and semi-finished)

• support during the development phase

• assembly

• NDT (non-destructive testing)

• heat and galvanic treatments, in collaboration with qualified and certified external suppliers

• specific technologies, combined with handcraft skills, for finishing processes (lapping up to 0,1 micron/meter)

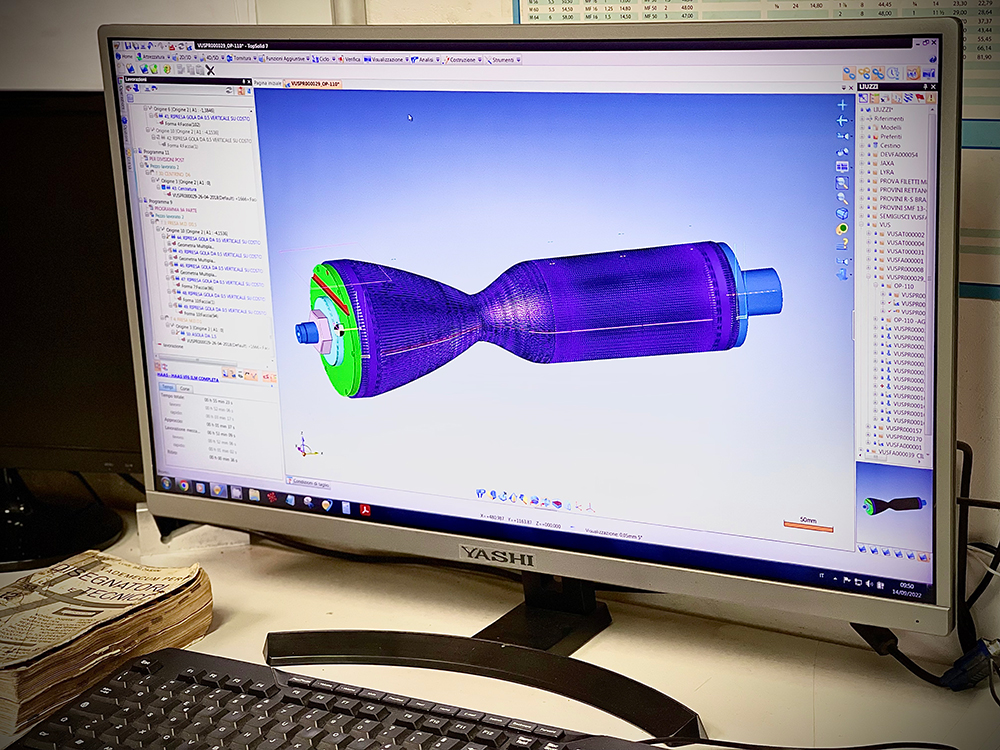

This Company is proud of its most advanced machinery for every type of mechanical processing, such as the 3, 4 and 5 axes numerical control milling machines, electro erosion, TIG welding, two calibrated and annually certified CMM coordinate measuring machines for dimensional inspection, and a measuring arm with laser scan for on-board measurements.

I.L.M. Srl uses programs such as CAD and CAM project design to develop its own activities, and an information management system that allows the tracing and coordination of the activities and production processes, and facilitates work cycle optimization, in order to offer the best performances and the most suitable solutions.